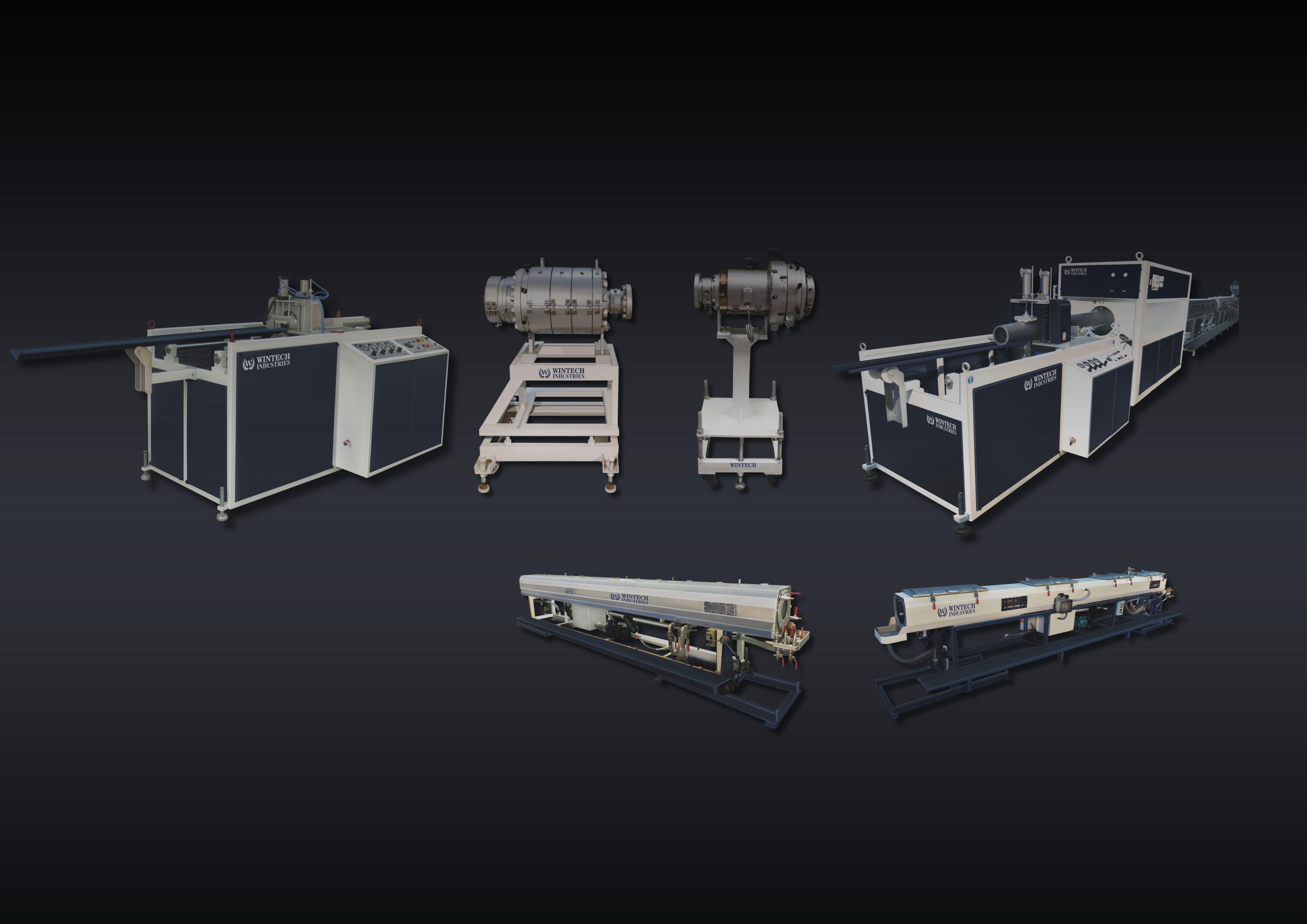

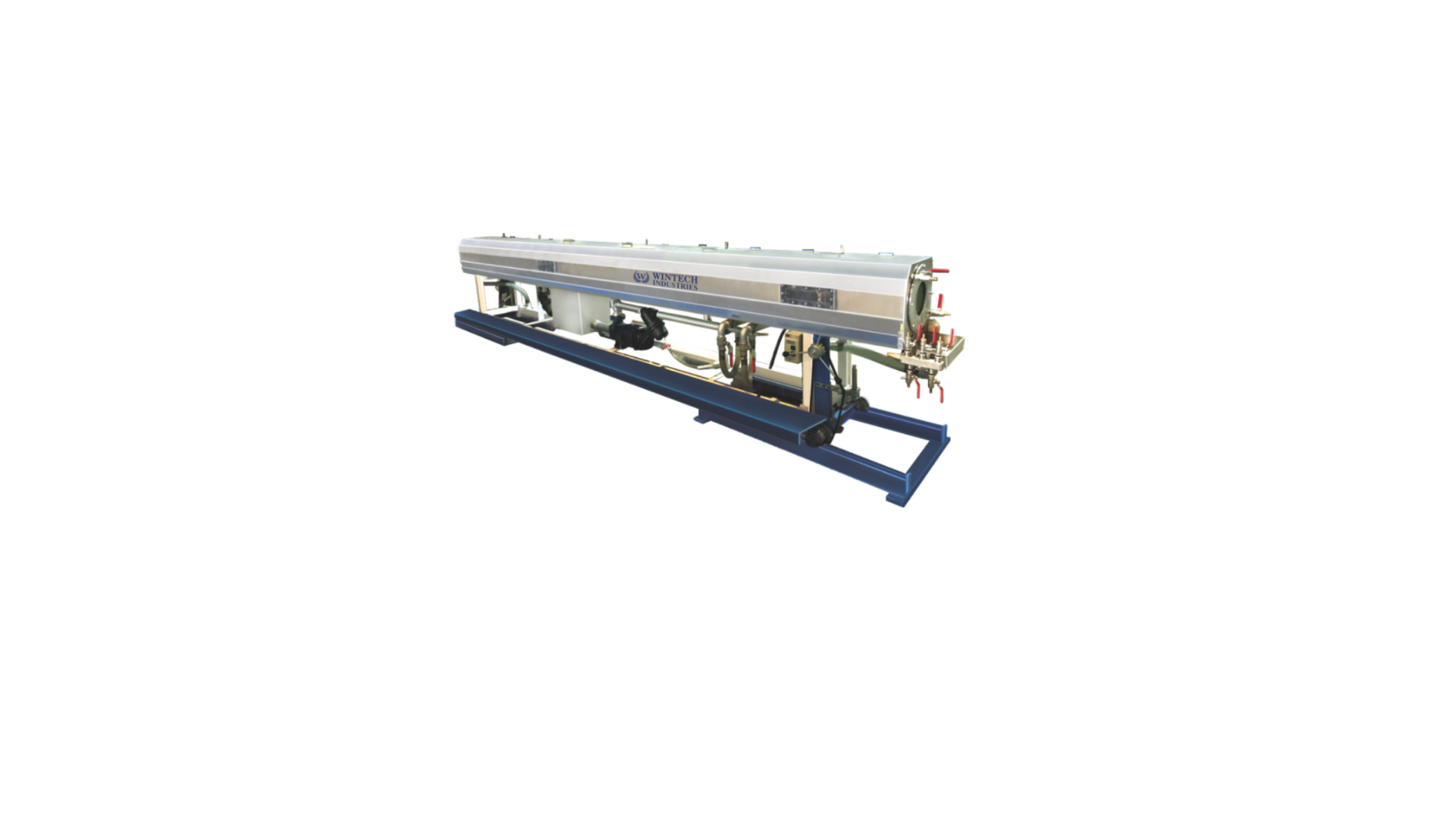

Die Heads (PVC)

-

High-Volume Low-Pressure design.

-

Suitable for single-pipe and dual-pipe production.

-

Uniform melt distribution.

-

Die head with trolley for easy movements.

-

80 to 100% utilization of extruders.

-

Twin Die is suitable for small size pipes with higher output.

| Model | Pipe Range (mm) | Output Capacity (Kg/Hr) |

|---|---|---|

| WP 63 | 20-63 | 100 |

| WP 110 | 20-110 | 200 |

| WP 200LV | 20-200 | 250 |

| WP 200HV | 63-200 | 320 |

| WP 250 | 90-250 | 425 |

| WP 315 | 110-315 | 550 |

| WP 400 | 110-400 | 700 |

| WP 630 | 250-630 | 1000 |

| Model | Pipe Range (mm) | Output Capacity (Kg/Hr) |

|---|---|---|

| WTDP 50 | 19-50 | 200 |

| WTDP 63 | 20-63 | 200 |

| WTDP 110 | 20-110 | 400 |

| WTDP 200 | 63-200 | 850 |